Information

- Publication Type: PhD-Thesis

- Workgroup(s)/Project(s):

- Date: November 2019

- TU Wien Library:

- Second Supervisor: Christoph Heinzl

- Open Access: yes

- 1st Reviewer: Rüdiger Westermann

- 2nd Reviewer: Gerik Scheuermann

- Rigorosum: 5. December 2019

- First Supervisor: Eduard Gröller

Abstract

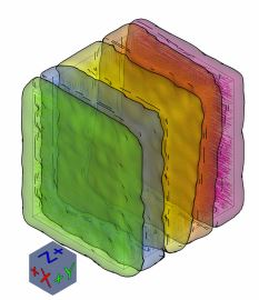

Advanced composites have excellent mechanical properties at low weight and can be realized as complex components that can be manufactured quickly and cost-effectively. Due to these outstanding characteristics, these materials are used in many di˙erent areas of industry, such as aviation and automotive. Industrial 3D X-ray computed tomography (XCT) is used as a non-destructive testing (NDT) method to inspect the quality of components and to develop new advanced composite materials. XCT has the ability to determine the inner and outer geometries of a specimen non-destructively. For example, interesting features in fiber-reinforced polymers (FRPs) such as fibers, pores, and higher-density inclusions can be detected. The high resolutions of modern XCT devices generate large volume datasets, which reveal very fine structures. However, this high information content makes the exploration and analysis of the datasets with conventional methods very diÿcult and time-consuming. In this doctoral thesis, typical NDT application scenarios of advanced composites using XCT are addressed and visual analysis methods and visualization techniques are designed to provide material experts with tools to improve their workflow and to eÿciently analyze the XCT data, so that domain-specific questions can be answered easily and quickly. This work describes a novel visualization system for the interactive exploration and detailed analysis of FRPs, a tool for the visual analysis and evaluation of segmentation filters to accurately determine porosity in FRPs, and a more general system for the visual comparison of interesting features in an ensemble of XCT datasets are presented. The results of the individual visualization systems are presented using real-world and simulated XCT data. The proposed visual analysis methods support the experts in their workflows by enabling improved data analysis processes that are simple, fast, and well-founded, and provide new insights into material characterization with XCT.Additional Files and Images

Weblinks

BibTeX

@phdthesis{Weissenboeck_2019_PhD,

title = "Visual Analysis of Methods for Processing 3D X-ray Computed

Tomography Data of Advanced Composites",

author = "Johannes Weissenb\"{o}ck",

year = "2019",

abstract = "Advanced composites have excellent mechanical properties at

low weight and can be realized as complex components that

can be manufactured quickly and cost-effectively. Due to

these outstanding characteristics, these materials are used

in many di˙erent areas of industry, such as aviation and

automotive. Industrial 3D X-ray computed tomography (XCT) is

used as a non-destructive testing (NDT) method to inspect

the quality of components and to develop new advanced

composite materials. XCT has the ability to determine the

inner and outer geometries of a specimen non-destructively.

For example, interesting features in fiber-reinforced

polymers (FRPs) such as fibers, pores, and higher-density

inclusions can be detected. The high resolutions of modern

XCT devices generate large volume datasets, which reveal

very fine structures. However, this high information content

makes the exploration and analysis of the datasets with

conventional methods very diÿcult and time-consuming. In

this doctoral thesis, typical NDT application scenarios of

advanced composites using XCT are addressed and visual

analysis methods and visualization techniques are designed

to provide material experts with tools to improve their

workflow and to eÿciently analyze the XCT data, so that

domain-specific questions can be answered easily and

quickly. This work describes a novel visualization system

for the interactive exploration and detailed analysis of

FRPs, a tool for the visual analysis and evaluation of

segmentation filters to accurately determine porosity in

FRPs, and a more general system for the visual comparison of

interesting features in an ensemble of XCT datasets are

presented. The results of the individual visualization

systems are presented using real-world and simulated XCT

data. The proposed visual analysis methods support the

experts in their workflows by enabling improved data

analysis processes that are simple, fast, and well-founded,

and provide new insights into material characterization with

XCT.",

month = nov,

address = "Favoritenstrasse 9-11/E193-02, A-1040 Vienna, Austria",

school = "Research Unit of Computer Graphics, Institute of Visual

Computing and Human-Centered Technology, Faculty of

Informatics, TU Wien ",

URL = "https://www.cg.tuwien.ac.at/research/publications/2019/Weissenboeck_2019_PhD/",

}

image

image PhD Thesis

PhD Thesis