Information

- Publication Type: PhD-Thesis

- Workgroup(s)/Project(s):

- Date: December 2009

- Date (Start): December 2005

- Date (End): December 2009

- TU Wien Library:

- Open Access: yes

- 2nd Reviewer: Ivan Viola

- Rigorosum: 11. December 2009

- First Supervisor: Eduard Gröller

- Pages: 105

- Keywords: marching cubes, feature peeling, difference measurement, multiple datasets, parameter visualization, comparative visualization, industrial computed tomography, volume visualization, fabrication artifacts, magnetic resonance imaging

Abstract

This thesis presents techniques and algorithms for the effective exploration of volumetric datasets. The Visualization techniques are designed to focus on user specified features of interest. The proposed techniques are grouped into four chapters namely feature peeling, computation and visualization of fabrication artifacts, locally adaptive marching cubes, and comparative visualization for parameter studies of dataset series. The presented methods enable the user to efficiently explore the volumetric dataset for features of interest.Feature peeling is a novel rendering algorithm that analyzes ray profiles along lines of sight. The profiles are subdivided according to encountered peaks and valleys at so called transition points. The sensitivity of these transition points is calibrated via two thresholds. The slope threshold is based on the magnitude of a peak following a valley, while the peeling threshold measures the depth of the transition point relative to the neighboring rays. This technique separates the dataset into a number of feature layers.

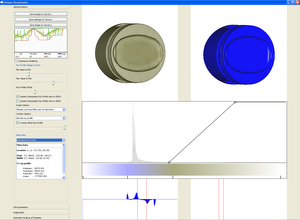

Fabrication artifacts are of prime importance for quality control engineers for first part inspection of industrial components. Techniques are presented in this thesis to measure fabrication artifacts through direct comparison of a reference CAD model with the corresponding industrial 3D X-ray computed tomography volume. Information from the CAD model is used to locate corresponding points in the volume data. Then various comparison metrics are computed to measure differences (fabrication artifacts) between the CAD model and the volumetric dataset. The comparison metrics are classified as either geometry-driven comparison techniques or visual-driven comparison techniques.

The locally adaptive marching cubes algorithm is a modification of the marching cubes algorithm where instead of a global iso-value, each grid point has its own iso-value. This defines an iso-value field, which modifies the case identification process in the algorithm. An iso-value field enables the algorithm to correct biases within the dataset like low frequency noise, contrast drifts, local density variations, and other artifacts introduced by the measurement process. It can also be used for blending between different iso-surfaces (e.g., skin, and bone in a medical dataset).

Comparative visualization techniques are proposed to carry out parameter studies for the special application area of dimensional measurement using industrial 3D X-ray computed tomography. A dataset series is generated by scanning a specimen multiple times by varying parameters of the scanning device. A high resolution series is explored using a planar reformatting based visualization system. A multi-image view and an edge explorer are proposed for comparing and visualizing gray values and edges of several datasets simultaneously. For fast data retrieval and convenient usability the datasets are bricked and efficient data structures are used.

Additional Files and Images

Additional images and videos

Additional files

Weblinks

BibTeX

@phdthesis{malik-thesis,

title = "Feature Centric Volume Visualization",

author = "Muhammad Muddassir Malik",

year = "2009",

abstract = "This thesis presents techniques and algorithms for the

effective exploration of volumetric datasets. The

Visualization techniques are designed to focus on user

specified features of interest. The proposed techniques are

grouped into four chapters namely feature peeling,

computation and visualization of fabrication artifacts,

locally adaptive marching cubes, and comparative

visualization for parameter studies of dataset series. The

presented methods enable the user to efficiently explore the

volumetric dataset for features of interest. Feature

peeling is a novel rendering algorithm that analyzes ray

profiles along lines of sight. The profiles are subdivided

according to encountered peaks and valleys at so called

transition points. The sensitivity of these transition

points is calibrated via two thresholds. The slope threshold

is based on the magnitude of a peak following a valley,

while the peeling threshold measures the depth of the

transition point relative to the neighboring rays. This

technique separates the dataset into a number of feature

layers. Fabrication artifacts are of prime importance for

quality control engineers for first part inspection of

industrial components. Techniques are presented in this

thesis to measure fabrication artifacts through direct

comparison of a reference CAD model with the corresponding

industrial 3D X-ray computed tomography volume. Information

from the CAD model is used to locate corresponding points in

the volume data. Then various comparison metrics are

computed to measure differences (fabrication artifacts)

between the CAD model and the volumetric dataset. The

comparison metrics are classified as either geometry-driven

comparison techniques or visual-driven comparison

techniques. The locally adaptive marching cubes algorithm

is a modification of the marching cubes algorithm where

instead of a global iso-value, each grid point has its own

iso-value. This defines an iso-value field, which modifies

the case identification process in the algorithm. An

iso-value field enables the algorithm to correct biases

within the dataset like low frequency noise, contrast

drifts, local density variations, and other artifacts

introduced by the measurement process. It can also be used

for blending between different iso-surfaces (e.g., skin, and

bone in a medical dataset). Comparative visualization

techniques are proposed to carry out parameter studies for

the special application area of dimensional measurement

using industrial 3D X-ray computed tomography. A dataset

series is generated by scanning a specimen multiple times by

varying parameters of the scanning device. A high resolution

series is explored using a planar reformatting based

visualization system. A multi-image view and an edge

explorer are proposed for comparing and visualizing gray

values and edges of several datasets simultaneously. For

fast data retrieval and convenient usability the datasets

are bricked and efficient data structures are used.",

month = dec,

pages = "105",

address = "Favoritenstrasse 9-11/E193-02, A-1040 Vienna, Austria",

school = "Institute of Computer Graphics and Algorithms, Vienna

University of Technology ",

keywords = "marching cubes, feature peeling, difference measurement,

multiple datasets, parameter visualization, comparative

visualization, industrial computed tomography, volume

visualization, fabrication artifacts, magnetic resonance

imaging",

URL = "https://www.cg.tuwien.ac.at/research/publications/2009/malik-thesis/",

}

Thesis

Thesis